New generation

notching with Nordic

traditions and quality

Lifetime warranty

Best quality

Best price

Unique technology ensure the best log cabins

Modern CAD CAM technologies that revive the best traditions of handcrafts, surpassing the aesthetic appeal of handmade cabins and precipitating a significant increase of trust in the quality of log houses.

The structural finish is the same as 300 or 500 years ago. Each log has its own size. You will not find two identical logs in any one project. This is the most natural environment for a person to live in.

Wall details

Walls are the primary component of a log house and represent the greatest surface area of logs composing the centre of the frame. The sizing of each log is carefully specified in CAD software and automatically included in bills of materials – with dimensions not of the parts themselves, but for blanks necessary in order to produce the parts. Thus, apertures are not included in the surface area of a wall, but the upper and lower parts generally contact a log, or cut into one, and thus the entire log must be considered as a blank for the relevant component. A similar situation is encountered with roofing support planes and gables, ceiling plank notches, decorative arches, log tips etc. For highly specific and routed parts, the dimensions of a log depend on the tool used to manufacture it. We recommend using our convenient web calculator for estimating the price of a frame – available under Pricing on our website. To accommodate for all the nuances described here, it includes 4% overhead in the surface area of necessary logs.

Roof purlins

The second most significant log house framework cost item is the set of roof load-bearing beams, also called purlins. These are generally round logs, although they may also be shaped like walling logs, without the notches. Rectangular profiles and glued solutions are also available. Importantly, the construction engineer assigned to the project must conduct a carrying capacity calculation based on run length, roof slope and the structural solution, as well as the snow load in the relevant region [kg/m2]. The customer determines the diameter, or minimal dimensions, of the purlins, as well as the number of purlins to use and the spacing between them. Log surface area tables assume that purlins come in the same thickness as walls, although practical diameters are up to 36 cm. This means that the volume of such logs would be much greater, although we ignore this fact in our surface area and pricing calculations to avoid an unnecessary headache. You can also update the calculation and keep track of each part of the frame, find it in the wall development drawings, make comparisons and make sure for yourself.

Posts, Columns

Support pillars and decorative columns. Solid or glued wood. For Post & Beam buildings, roof support seats, structural elements and diagonals. For balconies, terraces and banisters. Wherever. Glued columns are a more practical solution indoors, costing an average of 640 kr apiece. This helps avoid replacement every few years due to excessive splitting. Exterior air tends to have higher relative humidity, so solid wood columns work very well. Log surface area calculations assume that posts are as thick as the walls, although the actual dimensions are predominantly 25 (28) cm. Obviously, no square metre of log is sold cheap for no reason – we are looking to provide a price offer that is as objective and error-free as possible when we prepare a bid for a tender. We do it quickly, including tentative square meterage of logs, with comments and suggestions about the framework solution.

Floor beams

Beams between floors, profiled like wall logs but with no grooves, perfect dovetail joints at the tips. We recommend this kind of beam in order to stabilise the log house frame; they also have notches routed in the sides to facilitate clean assembly of roofs and/or floors. Quick and elegant, with no worries about corner beams. However, the beams may also be rectangular, square or even round. Solid wood or glued. You decide. This item, and the three items described above, are calculated together as the price of a log house. The total log surface area accurately reflects the materials requirements for a framework and the price of the structure at the same time. If you calculate the ratio of living area to log area, you see how cost effective the log house framework will be (lower ratios are better). Unfortunately, this ratio only describes the economic aspects of commissioning a log house.

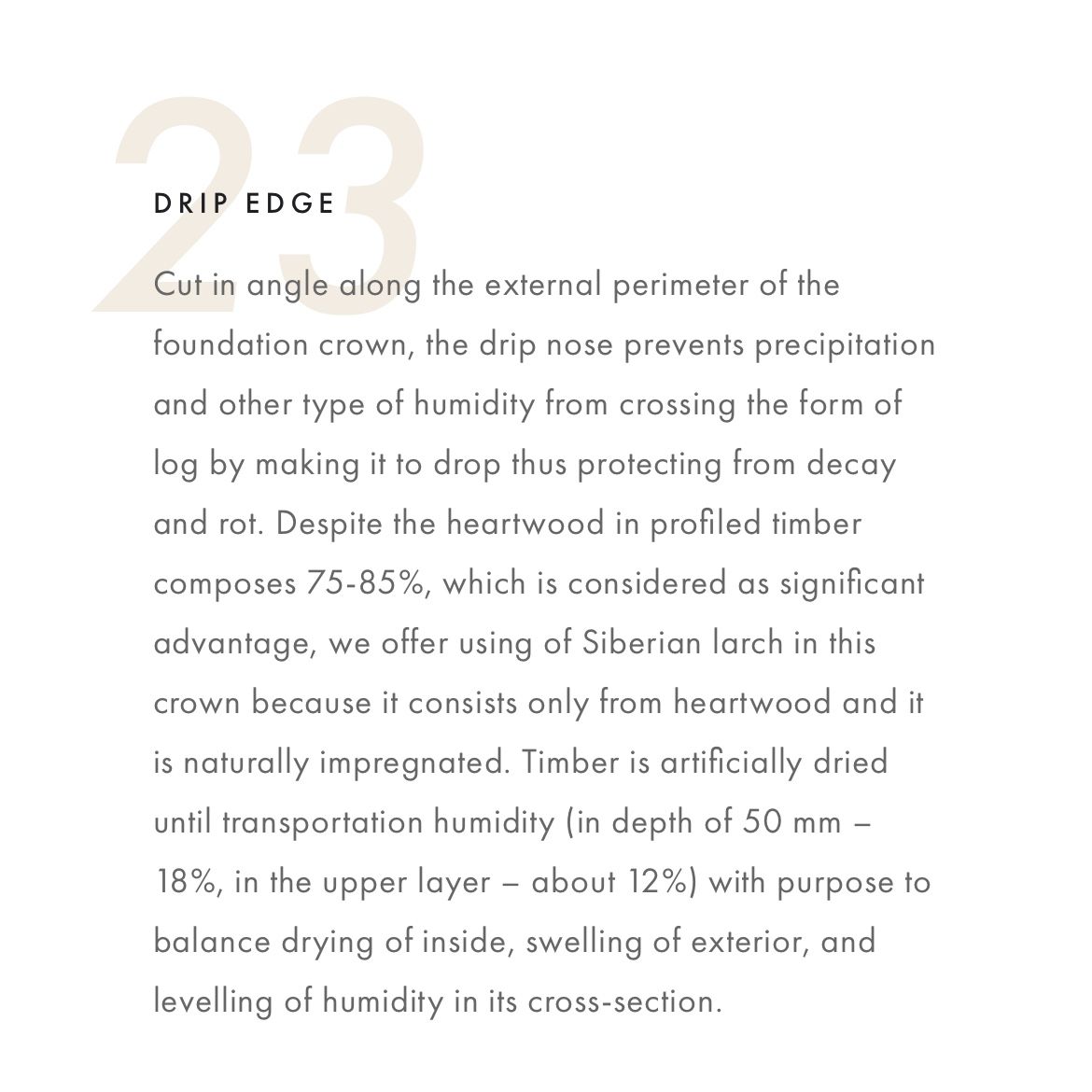

Rafters & Lathing, Planks

48x198 mm rafters to create the support framework for a roof. Rafters generally use lower ends, cut vertically, or vertically and horizontally, or according to a specific decorative profile of your choosing. A double layer of lathing is applied to the rafters crosswise, 48x48 mm, to enable ventilation under the roof. The two layers of lathing are included in the delivery package, but a third layer of lathing that increases thermal insulation costs 2800 kr/m3. Also, 48x198 mm planks are put between the ends of rafters, in the same sizing and expanded to 550 mm. This is consistent with the rafters interval and the width of heat insulation material. All mandatory, standard wood materials included in a delivery package (without customer involvement or choice) are dried out to at least 18%, calibrated, planed and cut to length.

Rails, Battens, Wedges, Slats

Press 48x48 mm or 48x96 mm lathing for additional roofing insulation. This is put below rafters to press the lathing to the ceiling planks – and, for the ceiling to snugly fit with purlins and not warp, for the structure to be able to settle. Between double press lathing are spacers placed perpendicularly, for the lathing to remain in a vertical position. The laying of ceiling planks (not included in delivery on account of extensive options to choose from) begins and ends with gable notches where the planks should be pressed to the bottoms of the notches. This is done with wedge lathing having dimensions 38x50 mm, placed in the notches above the planks and attached using wedges. Included in the package are 10x48 mm ledges, hundreds of metres. All film materials are attached to them, or through them. By the way, the 550 mm ledges also serve as spacers for positioning the first layer of lathing.

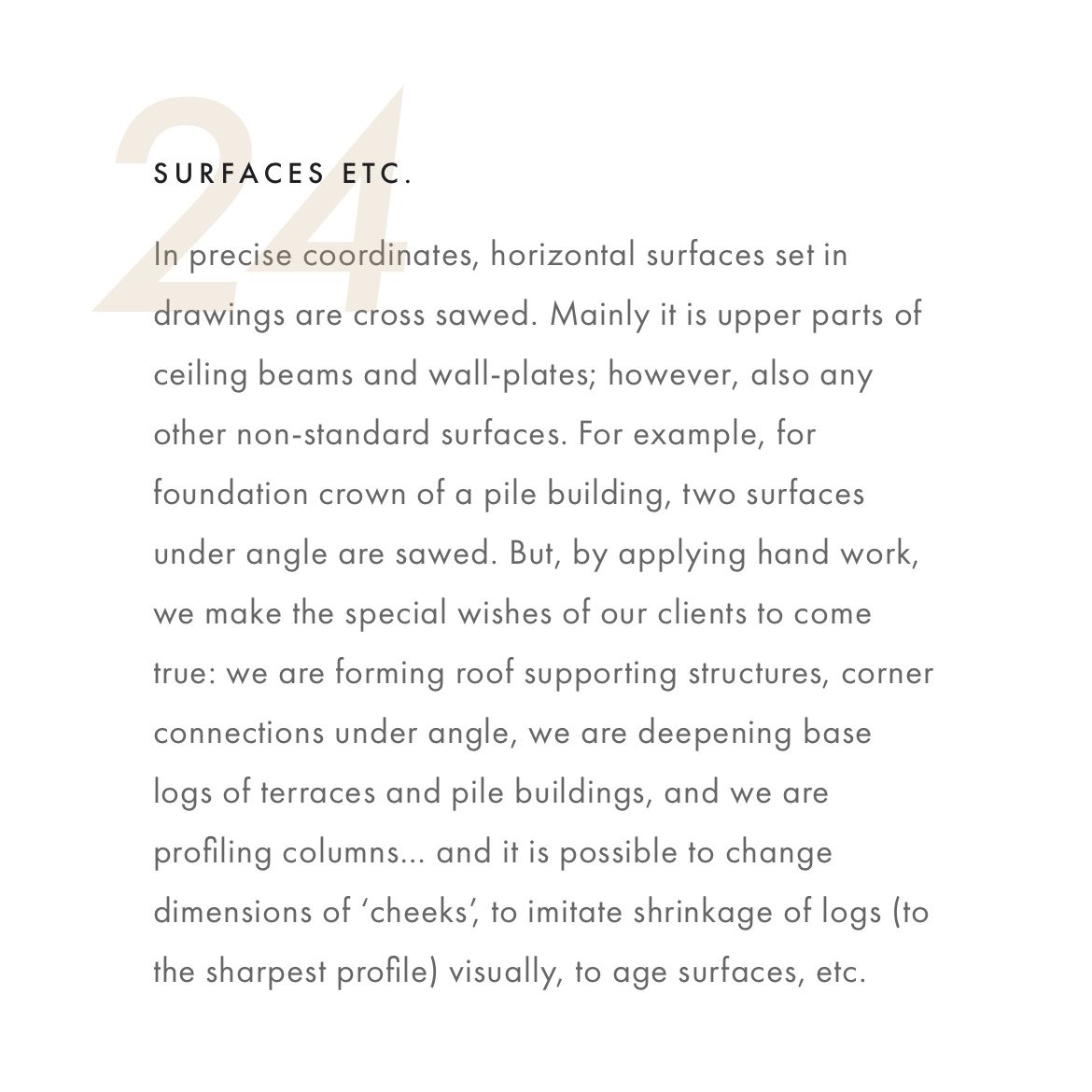

Sliding sets for apertures

Placed in wall openings for attaching windows and doors to prevent frame droop. In our case, the skid package consists of a 48x58 mm block and a 50x190 mm side plank. The plank has a 10 mm deep groove routed in the centre of it, into which to insert the block, glue it using PVA adhesive, and screw it down. This makes for a strong connection for both the block and the plank to function as a unit. This reinforcement prevents the deformation of notched log tips. Even more important here is the fact that logs always have holes drilled at a diameter of 60 mm in which to insert dowels. By the way, by allowing the installation of a door or window in a narrower section, thinner side planks may be used – down to 20x190 mm, which is the minimum. At the same time, installation spacing on both sides of the door/window frame is reduced. This may provide an additional 60 mm of frame or pane width.

Wall reinforcing pins

Dowels are profiled into an octagonal shape, with the intention of corners pressing into the sides of a drill hole. Large and strong dowels are necessary, they serve the purpose of “reinforcement” and must support the integrity of the log framework. The dowels are installed into holes drilled in logs to a diameter of 60 mm. Dowels of this size are sufficient for straightening out entire warped logs. Of course, systematic placement and sufficient numbers of dowels allow us to stabilise walls and unattached ends of logs. This comes with a guarantee. The total number of dowels in our projects is so high that they are considered with a consumable reserve. You may find the meterage near the end of the bill of delivery. If necessary, very long (2-3 metre) one-piece dowels may be installed along any drilling axis.

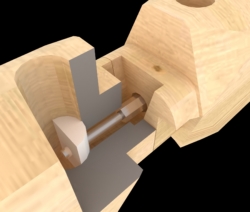

Steel-Nylon bracing ties

Any log longer than 8 m, and any highly specific part, will be screwed together on the inside of corner joints. Joint locations are visually concealed with a transverse beam. Unique fasteners are used for connecting the tips, or halves, of logs – these are included in the delivery package. Fasteners consist of high-strength nylon semicircles and zinc-plated bolts. There is no metal-to-wood contact, preventing damage to wood due to rot or metal corrosion. They can resist 6-7 tonnes of tension and, elastically compensating for the settling of wood as it dries out, prevent the corners from de-tensioning. That is, when the semicircles are initially pressed into the wood, it allows the wood to squeeze them out over time, guaranteeing a tighter connection with no gaps. The package self-cost is at least 87 kr, and an average house has 70 of these tension joints. Let us add that assembly by hand involves the use of a metal staple with a diameter of 6-8 mm.

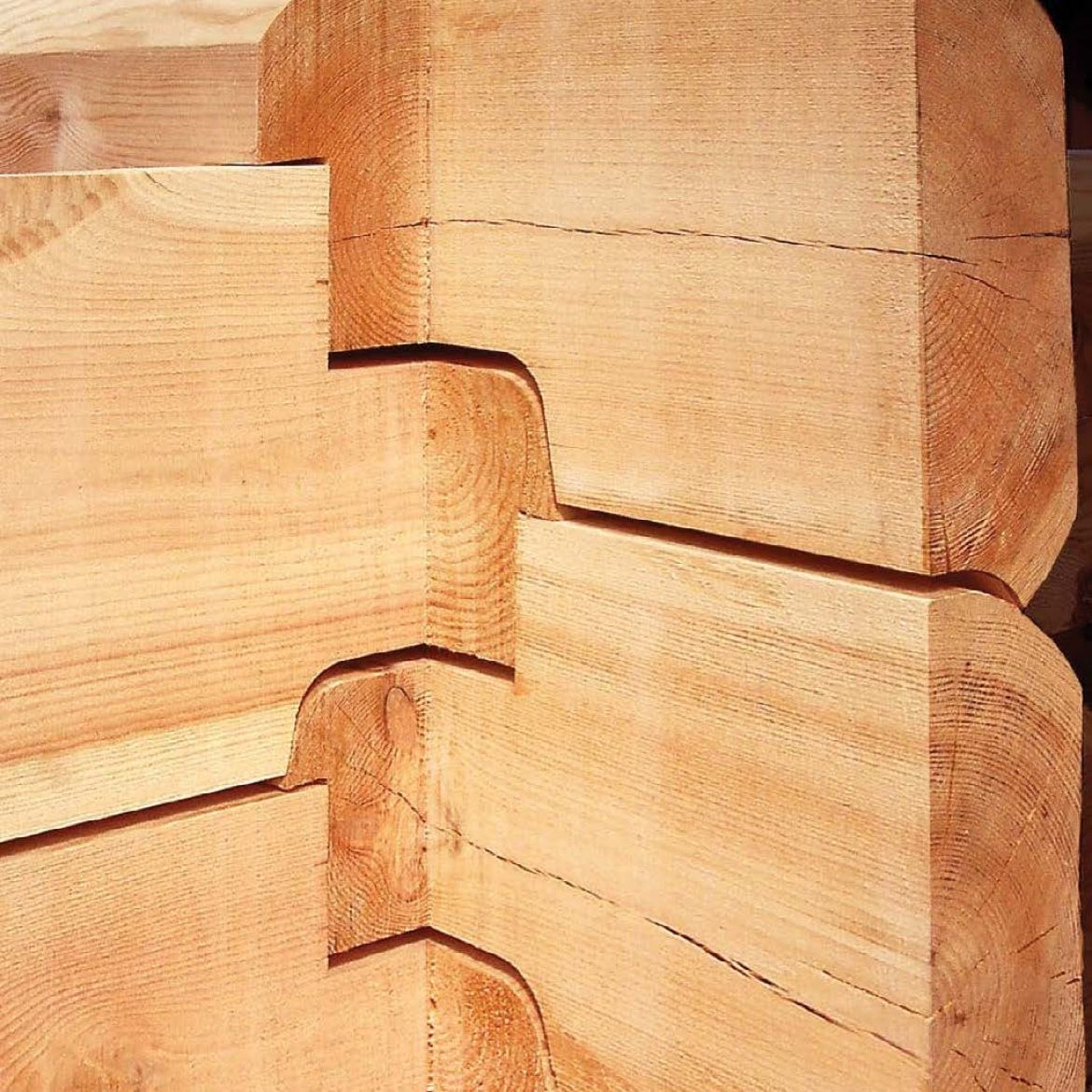

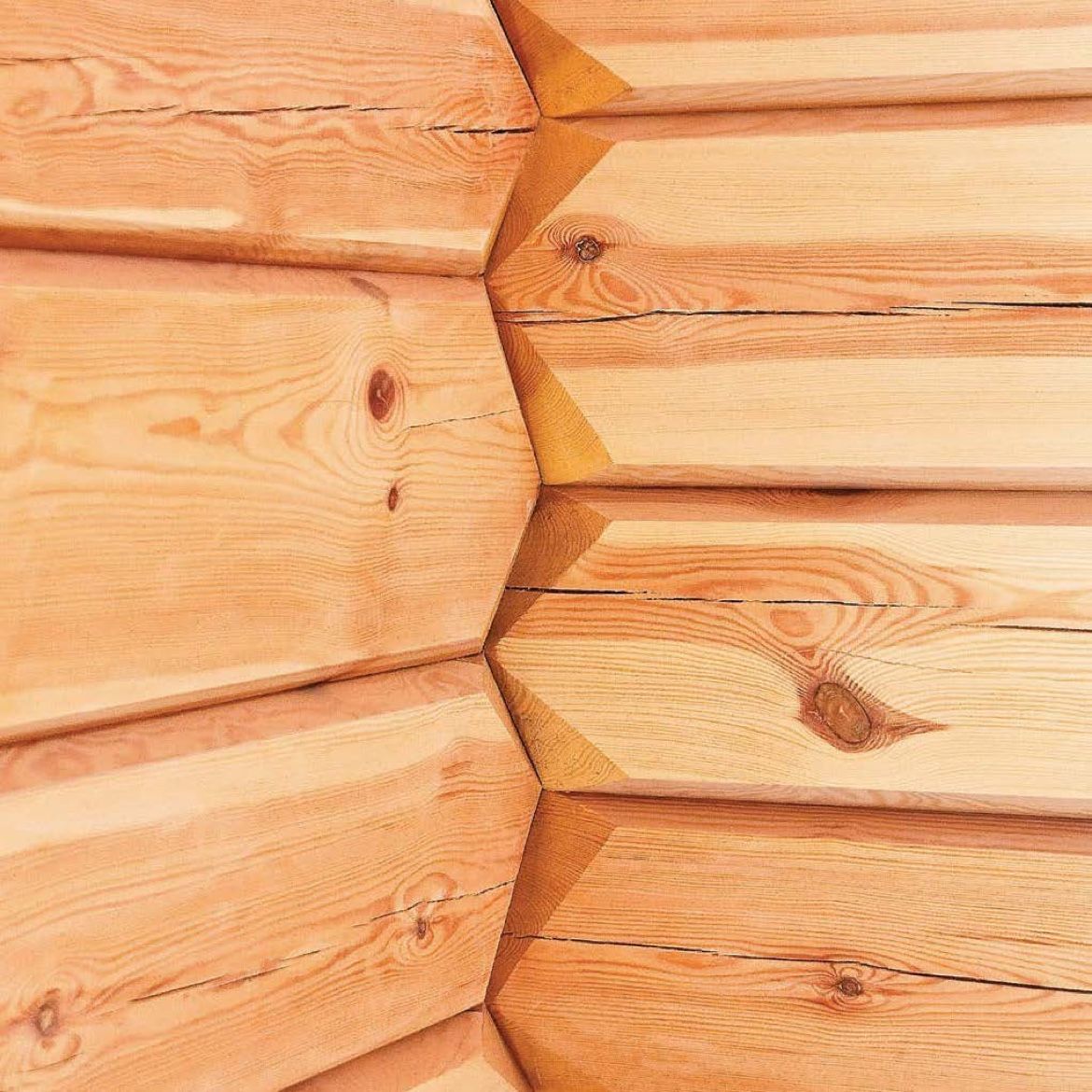

Corner

The traditional scandinavian connection of corners. Historically, its construction was improved by solving problems of settling and heat-stability, by reducing impact of log torsion and origination of gaps. Internationally, it is acknowledged as the most complicated one! Applying modern CAD-CAM processing, the theory was effectuated in praxis: structure and properties of connection are approximated to the ideal. Absolute conformity to traditions is preserved in combination with correct proportions of connections, cleanliness of forms and lines, guaranteed geometry of settling and over-measure, controlled effort, radical protection against wind, preciseness, a.o. qualities.

Foundation crown

The foundation crown is formed by 100 mm to 300 mm high logs with straight base. All connections are made in strictly regulated division of proportions in range from 100 mm to 190 mm. In contradiction to the typical corner, the angle-like ‘cheek’ surfaces are cut only to the underneath log by letting bases to achieve the zero level. Besides, by improving the connection structure, additional cams are made to adverse sides for filling of internal voids. Both base of logs and preciseness of central plugs and respective sockets prevent logs from torsion while comb-type effort seals contacting lines of the connection additionally.

Dovetail

The dovetail is introduced into the end of a unilateral, not through-going corner connection for hiding of ends of cross wall and other logs in the walls. Preciseness in combination with the massive construction assists in prevention of lateral movement of cross logs from this asymmetric connection. In addition, seizing of sides of the dovetail fixes it and subjects to the tensioned effort. In order to strengthen problematic joints, the connection might be modified with a half of typical corner. Settling over-measure (10 mm) is cut in upper and/or underneath part of the log; and its edges press into the adverse side of the connection, namely, in the end of the wedge-shaped settling slope.

Reverse joint

This special connection is applied in cases when ceiling beams, profiled roof purlins have to be located in a specific height, a wall or other structure has to be started. Only by turning the detail to the other side in virtual reality and cutting other 120 mm socket, connection with the next typical corner will be provided. It mainly refers to profile without groove joint. For all connections of subtypes, upper and underneath points of ‘cheeks’ go into one point. As the structure settles, the symmetric and angle-conic formation of ‘saddles’ facilitates self-closing of contacting lines of the corner; and, at the same time and together with the central plug, it does not let logs to twist.

Combined joint

Combinations include transition from a through-not-going, dovetail connection to a through-going corner connection or vice versa by changing the profile simultaneously. Such connections are quite rare and usually located in premises; therefore, the most complex hybrids do not have wind protection Groove and Tongue. In design, it incorporates in the common philosophy: every detail has to be inimitable or unique and to cross freely and differently with details of related walls. The program tests all divisions of proportions with no permission to wrong (too steep or too flat) connections. Cut with non-standard CNC equipment; summary preciseness ± 0,5 mm.

Purlins joint

Purlins are turned in diameter from 220mm to 360 mm basing on their strengths or aesthetical considerations. Connections fully conform to structure and characteristics of a typical corner. Larger amount of division versions is allowed thus increasing manoeuvrability in designing of complicated crossing roofs and other complicated joints. These attractive elements will contrast lively and distinguish if diameters of nearby purlins differ for at least 40 mm. Diversity of sizes for purlins and profiled logs impart naturalism; in addition, impression of industrially manufactured product is erased by obtaining all its advantages and qualities.

End joint

Joint connection knits together long (>8 m), specific details. It is logically, and, if possible, in turns, hidden in the most appropriate crossing point of corners. Also the set of bracing is inserted internally: horizontal and vertical drills are connected in a unified depth. The steel wedge is braced, fixated, tensed to the desirable direction so contacting lines of the connection are slightly pressed. This and deformation from effort can be naturally recovered by performing multiple local humidifications: impressions will straighten up. It is a unique method for closing of gaps in places where they have formed by time in spite of preciseness and theory.

Tongue & Groove

The central plug is from both sides prolonged with small tongue or pin; and it has also a respectively cut groove in depth of 10 mm (height of ‘wind’ pin for purlins is from 20 mm to 30 mm). It covers the weakest place of corners, forms barrier against wind and snow, increases heat-strength, and reinforces the cross-section. Width of this match, groove joint, central plug, and socket is equal: exactly 120 mm. All together they do not permit torsion of details and exclude the possibility of incorrect installation. In addition, the connection is sealed by the already mentioned 1-2 mm effort, which comb-type impressions in the surface of ‘cheeks’ form additional labyrinths and improves the adherence.

Profiles

By copying historic methods of shaping, – profiled as two-sided logs with sharp profile edges for transition to side surfaces. By understanding the processes of settling, – coordinated profiles of log upper part and joint groove. By using only logs of large height, – harmonic, proportional compatibility with thickness was reached. The deeply sitting (12 mm), universal profile, appropriated also for angle (5º) sloping of overhangs by protecting them against precipitation. Two types of profiles are offered: one is sharper, with different lines, and the other is more rounded and regular. 3 main types of profiles: grooved, non-grooved, saw squared, and, of course, also turned purlins.

Transition of profiles

Having respect to traditions, harmonic, aesthetic constructions, and cleanliness of structures, despite technological complications, there is provided transition from non-grooved to grooved profile in scope of one detail. It is needed for transition to terraces, beams, balconies, decorative aisles, log ends, and other structures, where implicitly only non-grooved profile shall be used. In case of possibility, longer details are knit together by butt joint without taking additional risk with defects of groove lines when applying hand work. Such details can be mutually connected with all profiles by using any type of connection.

Original profile

Classical, sophisticated log profile with sharp edges, extended side width, and typical shapes created during the process of hewing. The natural character of the profile is shown by its asymmetrical differences - straight lines on the top part and curved lines on the bottom part of the log. Bottom of the log is flattened on purpose to make it look visually wider. This authentic profile gives any log house a character, by proving how rigid are the walls and how tight are the corner notches. Profile to achieve exceptional integration of your log cabin with the environment and to suit every taste.

Regular profile

A simple and modest profile, made close to a shape of a round log, creating a gentle overall image of the building and boosting the warm and cozy atmosphere of a log house. The profile is featured with symmetrically rounded corners, so that the joint with the side would not be as visible. It will be a better fit in a rural environment or among similar buildings. In this way an impression of lighter, freer construction is created by imitating natural roundness, by simple shapes & eased perception. Profile to achieve exceptional integration of your log cabin with the environment and to suit every taste.

Ascetical profile

The frame and scope of this urban profile is the V-shaped groove, which is a traditional part of hewing. The groove fearlessly exhibits the triangle as the main shape of the design, as well as it features only straight, sharp edges and sharp corners. The profile has a low settling interval, very wide sides, and minimal separation [also triangle] between the logs. The improved groove barriers increase heat and wind resistance, as well as prevent sides of the beams from cracking. Profile to achieve exceptional integration of your log cabin with the environment and to suit every taste.

Log dimensions

The height of profiled logs (from 200 mm to 340 mm, step 10 mm) offers many possibilities for unique and as much as possible contrasting combinations not only in crowns but even in scope of them. Providing accurate control of dimensions and connections, a lively and aesthetically unobtrusive product was obtained as well as elasticity for reaching of required heights and optimal tie of structures was ensured. Grooved logs have even numbers and non-grooved – odd numbers of heights. In fact, to the height of logs 12 mm or 24 mm shall be added if their mutual overlapping is considered. Wall thickness: 200 mm; in the nearest future: 150 mm and 250 mm!

Purlin dimensions

Round, calibrated roof logs. Purlin length up to 8.1 m. Diameter from 220 to 360 mm, in 10 mm increments. A wide range of sizing, excellent options for combining these logs with the walls and adjusting to roofing intervals, axis spacing and load-bearing capacity ratings. This allows us to reach heights with exact angles etc. This makes it easier to solve for designed parameters, creating a lively, contrasting appearance with the use of logs of different diameters next to one another. There are cost savings with smaller but sufficiently sized logs. Extremely deep or shallow joints are also possible without violating the verticality of “cheeks”. A 22 cm purlin connection may have a ratio of 6/16, a 36 cm purlin - 8/28 etc. Clearly, it is ideal to divide in half, but, without these deviations and the range of available dimensions, it would not be possible to combine everything with the framework.

Floor beam dimensions

Standard 200 mm beams profiled like wall logs, without grooves. Designs may vary in height between 200 to 310 mm – this also applies to beams 150 mm and 250 mm thick. The maximum length of a beam is 8.1 m, in profile increments of 10 mm. The choice of beam sizing is mainly determined by indoor run length and the load-bearing capacity of the beams. Most often, the size of the visible (decorative) lower part of ceiling beams, which is selected by the customer, is also important. We highly recommend this kind of beam. It stabilises the log house framework, with notches routed into the sides for proper ceiling assembly. Quick and elegant, with no ledges. For rectangular and round beams, there are no sizing limitations (and no length limitations for glued beams) because they are installed in walls by hand. Non-standard beam sizing is determined by the designer and the customer.

First crown dimensions

The foundation row is composed of logs 100 mm to 300 mm tall with a level base. Increments of 10 mm, allowing for 21 heights of semi-logs. In other words, 10 small foundation row profiles between 100 and 190 mm, and 11 large foundation row semi-logs between 200 and 300 mm tall. Based on aesthetic, structural and mathematical considerations, the arrangement of walls dictates which orientation starts with small logs and which one with large ones. This dilemma is substantially simplified by the available variety of sizes. There are ways to combine logs between – and within – a foundation row in a way that is varied, unique, and contrasted where possible. The result is a natural, aesthetically unobtrusive product, with flexibility in accomplishing desired heights, and optimal structural connections.

Settling & shrinking

Unified span in connections and between details, limited angles of ‘cheeks’ and other extremes, sorted bent-fibred logs, conic, proportionally increasing formation, and equal effort of contacting lines provide homogenous structure, identical conditions of settling (1÷3%), minimal risk of complications, and smooth course of the process. The initial settling and drying is compensated with the effort of connection while the wedge-shaped (0-3 mm) slope is intentionally lifted for 2 mm in order to lay on ‘saddles’ only at the end of this stage. As the wood continues pressing for many years, spans and over-measures invisibly shrink.

Stretch of corners

Tensioning is performed along “cheek” contact lines with subsequent corner joining. The dimensions are easy to set in the CNC parameters and remain consistent for the entire house – which is of enormous importance. The most frequent tensioning parameter is +1 mm. It is adjustable depending on the thickness of insulation material between logs, or may accommodate a customer’s preference for tighter connections. Tensioning of between -1 mm (for linen tape) and +2 mm (for semi-synthetic wool) is generally chosen. With tighter tensioning of +2 mm, framework assembly will take slightly longer and require more work, but after about a year you will be able to wet the wood around “cheek” contact lines (3-5 times) and seal the shrinkage gaps should they appear. During assembly, squeezed grooves will stretch back out. We guarantee this because of the characteristics of wood. “Extra” tensioning cannot be accomplished given execution by hand.

Planes

For support of rafters, ceiling, and other roof structures, - surfaces (unlimited in angles) or differently broken planes are milled in previously defined length, almost in every depth and distance from the centre. Simple, with cam, broken, divided into two heights and ridge planes, from one or both sides grooved surfaces both left and right ones. It is important that just in the process of designing, the optimal layout of complicated (perpendicular, of one height) roof support planes are solved. The ribbed milling provides very clear lines and facilitates contact of surfaces. Planes for purlins are prepared with bandsaw.

Gables

Side edges of ceiling and boarding are hidden in roof triangles by cutting with precise coordinate equipment. Grooving of any amount, side and orientation as well as partial, through-not-going (at side walls) grooving with freely changeable angle. For exterior: in depth of 35 mm; for interior: in depth of 60 mm; namely, before or behind the edge of the groove joint. An absolutely straight groove continues in all details; and perpendicularity of its edges guarantees precise installation. The boarding is concretely pressed and fixed if pressing lathes are wedged into the groove. The middle cam works as a heat barrier and convenient transition between sides. Milling width – 60 mm; it is appropriated also for simple cutting of frontons.

Surfaces etc.

In precise coordinates, horizontal surfaces set in drawings are cross sawed. Mainly it is upper parts of ceiling beams and wall-plates; however, also any other non-standard surfaces. For example, for foundation crown of a pile building, two surfaces under angle are sawed. But, by applying hand work, we make the special wishes of our clients to come true: we are forming roof supporting structures, corner connections under angle, we are deepening base logs of terraces and pile buildings, and we are profiling columns… and it is possible to change dimensions of ‘cheeks’, to imitate shrinkage of logs (to the sharpest profile) visually, to age surfaces, etc.

Apertures

Upper and underneath parts of all apertures have to be prepared; for lintels of decorative arches transition of profiles is made. It is significant to calculate correct over-measures of settling and to approach the external edge of upper and underneath detail only in exceptional cases. It may be effectuated only if all complications and conflicts are averted during the process of designing. Heights of apertures are usually equal; and only by combining heights of walls and base logs, by changing amount of crowns, an optimal, often the only solution appropriated for all walls can be found. Everything is connected; also beams and purlins define several, sometimes all, crowns under them. Installation of windows and doors in wall openings is enabled with a skid package consisting of a notched side plank and a block glued and screwed into this notch. This reinforces the structure and prevents the deformation of notched log tips. To find out more about this skid package, refer to section 7 above.

Arcs

Having respect to wishes of our clients and traditions, decorative arches, upper and underneath polls of overhangs, rounds of aisles or other cuts of ends are scribed with patterns of different range and form and, temporary, sawn off and grinded applying hand work. There is individual approach to every decorative arch and poll by including details of sufficient length in the project. In the nearest future, these complicated, regular, and free forms will be connected with height and position of every separate detail in the project and cut by using programmed large-sized CNC machines.

Grooves

Industrially cut trough-going grooves (width 60 mm) for installation of windows, doors, columns, ceiling etc. Regulated depth, clear performance, precise surfaces. Through-not-going grooves are hand work; therefore, defects of cuts are possible. Limitations set by the program define that by designing of ceiling grooves in the beams, offsets from inconvenient places of profile are followed, namely, 10 mm before (upper part) and after (underneath part) the side surface edge. Grooving for laths of boarding and cross-wall places is possible to cut as well. High-quality, grooved ceiling perimeters and edged beam tops at no extra cost (planking between beams is very labour-intensive). To avoid excessive details such as corner & floor ledges, we suggest joining the floors and walls directly - with precision - using grooves.

Floor beams

In scope of a unified, natural style, the structural element of the building is highlighted. Calculations of strength, demands for heat or sound insulation as well as aesthetic considerations define the height of beams (non-grooved profile, from 230 mm to 310 mm), regulate heights of beam upper and underneath parts and grooving. The result of the complicated designing work is not compromise only between beams of different directions, but also between grooves for ceiling in beams and cross walls. Corner connections provide logical, rigid tie with walls by reducing problems of beam settling and torsion. In addition, lying or groove for ceiling has been simplified considerably: it is elegant and without slats.

Drills for cables

Vertical (Ø 60 mm, through-going or hidden) drills for electrical and other channels defined by the customer. Horizontal (Ø70 mm, until centre, one-sided, double-sided) drills for multi-place sockets and dividing boxes. Drills of different meaning are coloured differently in the drawings. Vertical, horizontal drill holes and milling in all the places where channels are designed to be. In perfectly straight lines, adjustable sizes, at no extra cost. During wall assembly even water-pipes and drains at Ø 50 mm can be fitted in. We recommend combining these holes with horizontal grooves and milling, see also point 34.

Drills for pins

Vertical (Ø 60 mm, through-going or hidden) drills for wall pins, settling bolts and similar wall stabilizers. Drills of different meaning are coloured differently in drawings. Increase of pins (massive octagon with tendency to cut into sides of the drill hole) amount and systematization of their application has improved stability of walls significantly. Accurate performance of drills eases the installation, pinning in every 4 crowns becomes safe; and even hammering of one-piece pin becomes theoretically possible. Seamless pins, their systematic arrangement and number will stabilise the walls and free wall ends, and will straighten out twisting logs using force. You can find out more about pins also in the point 8.

Drip edge

Cut in angle along the external perimeter of the foundation crown, the drip nose prevents precipitation and other type of humidity from crossing the form of log by making it to drop thus protecting from decay and rot. Despite the heartwood in profiled timber composes 75-85%, which is considered as significant advantage, we offer using of Siberian larch in this crown because it consists only from heartwood and it is naturally impregnated. Timber is artificially dried until transportation humidity (in depth of 50 mm – 18%, in the upper layer – about 12%) with purpose to balance drying of inside, swelling of exterior, and levelling of humidity in its cross-section.

Benefits

Wellness eco house

The smell of pine wood, real solid wood. Balanced air exchange and moisture. Absolutely ecological and natural microclimate with the only construction material of

The smell of pine wood, real solid wood. Balanced air exchange and moisture. Absolutely ecological and natural microclimate with the only construction material of organic origin. It becomes easier to breathe and your life force is replenished faster, the body’s protective capabilities and immunity of improves, your general tone and joy of living increase. The feeling of home. Natural log shapes, the calming touch of handwork. The aesthetically pleasing, live view of the walls of the building combining logs of different heights.

Highest quality

A warm and safe house. The whims of individual logs are under control. The advanced, industrial-quality built CAD and CAM technology is finally available in the field of log

A warm and safe house. The whims of individual logs are under control. The advanced, industrial-quality built CAD and CAM technology is finally available in the field of log house construction. It incorporates the knowledge of ancestors, the competence of engineers and programmers, introduces real innovations and leverages woodworking techniques available in 2023. Accurate and correctly built log houses. Fundamental improvement in handicraft. Contentment of professionals. Transformed labour-intensive and archaic log treatment techniques, but with no haste or simplification.

Authentic and traditional

The configuration draws from the wood building traditions and experiences of old masters. The classic of the log house genre. The authentically replicated norwegian

The configuration draws from the wood building traditions and experiences of old masters. The classic of the log house genre. The authentically replicated norwegian interlocking structure of house corner connections cherished for many centuries. During production, the value of each log structure, every hand-crafted detail has been considered and adapted to the task. Advanced corner connections, with a logical structure, with a historically proven value. Log heights variation and selected shapes. Great for people who enjoy life. Timeless style.

Reasonable and fair price

For next-generation log houses. For a number of excellent improvements: tongue & groove for sealing corners, adjustable stretch, increased pin diameters and

For next-generation log houses and number of excellent improvements: tongue & groove for sealing corners, adjustable stretch, increased pin diameters and numbers, hidden installations, grooves, flexible log ties etc. For extensive design adjustment opportunities and involvement of the customer in production of framework - the most important part. For all guaranteed and stimulating factors. For the manufacturer’s cost estimates and considerably more attractive price, for considerably higher quality compared to the market average, with no overcharge.

Customized frame

Scandinavian type of log house and corner connections. From your idea and design to a finished framework. Customized design, special structures and installations.

Scandinavian type of log house and corner connections. From your idea and design to a finished framework. Customized design, special structures and installations. Includes all your wishes and visions – modern, classical, conservative, daring. The CAD designing program combines logs of different heights, the CNC management equipment ensures excellent execution. A fully controlled and digitally managed process. A unique combination of details, handicraft style, and hand-made accents. Everything is possible.

Everything with a warranty

Guaranteed processing accuracy, performance quality, stability of log structures, even shrinkage, building pressure resistance tests, and the best frame pricing. With

Guaranteed processing accuracy, performance quality, stability of log structures, even shrinkage, building pressure resistance tests, and the best frame pricing. With due care for quality, of course. Experience and competence, 20 years in CNC. High log quality standard. Quick mounting and other cost savings. In the course of building assembly: log copy, express delivery, replacement. During the building shrinkage period: After-sales Service Agreement. Your log house will certainly serve several generations of people. With a warranty.

References

Traditions