CAD CAM tandem of digital technology successfully adapted to the industry of log houses. A good example of the transformation of folk crafts, with respect for tradition and craftsmanship. New generation log buildings and beautiful farewell to old and degraded working methods. CNC equipment replaces chain saws, grinders and sledge-hammers so beloved by carpenters. Great innovation and progress, with respect for trees. 100% natural and pleasant homes.

Process

① Modelling of individual frames

② Processing with CNC equipment

③ Creation and control assembly of craft elements

④ Delivery of finished parts and structures

⑤ Log building assembly, almost like Lego

Result

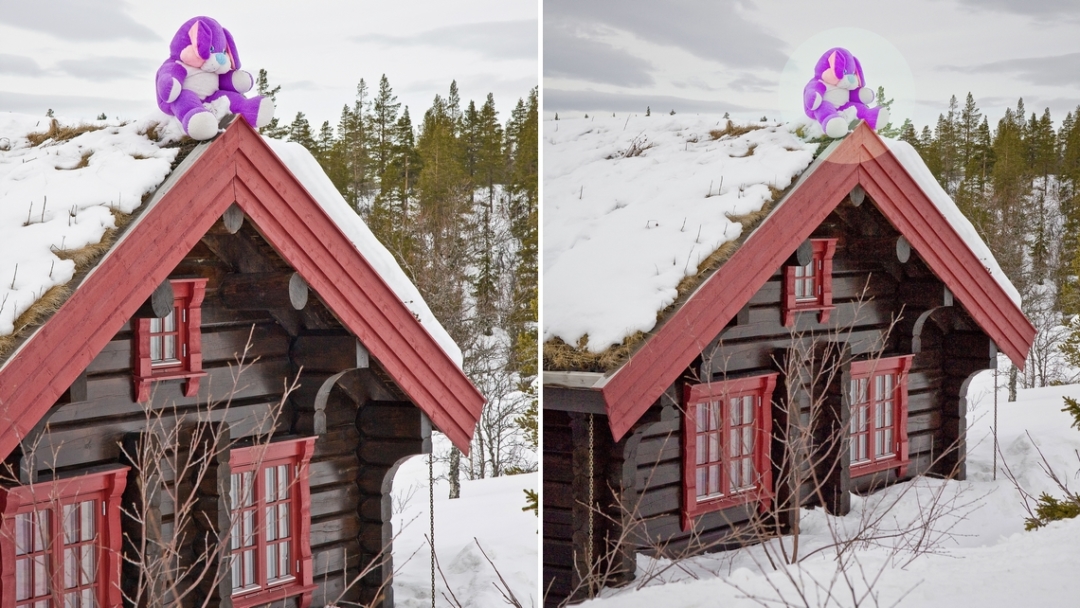

⑥ Solid pine log buildings completed with roof structure timber

⑦ A product that meets modern requirements is precise and accurate

⊕ To achieve integration with the surroundings, we offer 3 log shapes, according to your taste

|

|

|